Key Benefits of AI Analytics

Drilling dynamic module

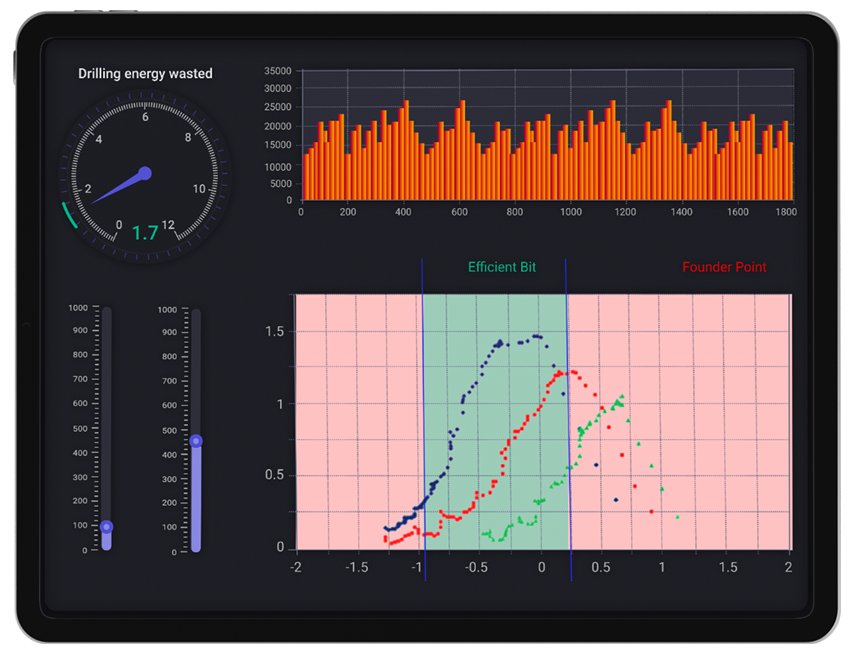

Through advanced data processing on site, Cyberloop provides drilling dynamics with Rockstrength and Drillsaver.

Predictive maintenance

Using data from C-DAQ or any other data acquisitions system to anticipate potential issues with equipment or in the working process.

Real-time monitoring

Real-time MSE (Mechanical Specific Energy) monitoring for rock strength classification, hole cleaning index and early bit wear detection.

User-friendly

User-friendly visualization module helps driller immediately react on issues and enables perfect weight transfer and suitable settings to minimize energy wastage.

Features

Full control over the processes:

– Early drilling anomaly detection

– Real-time Friction Factor monitoring index to indicate hole cleanliness and drag coefficient

– High-speed scanning of Drilling Dynamics parameters

– Energy profiles tracking on multiple RPMs to detect flounder point

– Prediction of potential issues with equipment or in the working process before such issues lead to failures, breakdowns during operations or process interruption

Equipped with alerts and prompts:

– Stick-Slip alerts and advanced diffT alerts

– Drilling failure mechanism detection

– Torque power spectrum

– String stretch and top drive vibration detection

– Advanced drilling advisory module